Rapid, low-cost prototypes & parts delivered globally in 10 days

- 100+ metals & plastics, 50+ surface finishes

- Instant quotes for 1-1,000 parts

- Lead times from 3 business days

Rapid, low-cost prototypes & parts delivered globally in 10 days

- 100+ metals & plastics, 50+ surface finishes

- Instant quotes for 1-1,000 parts

- Lead times from 3 business days

One-stop End-to-End Product Development Service

From Prototyping to Mass Production

At Zigitech, we provide high-quality, cost-effective rapid prototyping, rapid tooling, low-volume manufacturing, and mass production services tailored for startups, SMEs, and large enterprises. Our team of 50+ skilled engineers (with 10+ years of industry experience) supports your entire product journey – from design validation to bulk production – using advanced manufacturing technologies like vacuum casting, CNC machining, plastic injection molding and a range of finishing services. If you’ re ready to start your next project, please contact us today for a quote.

Rapid Prototyping

With advanced tech and experience, we deliver prototypes in 3 days and cut costs by 30%, offering CNC, vacuum casting, rapid tooling, sheet metal, and 3D printing.

Low-Volume

low-volume manufacturing for fast market testing and inventory control, using CNC, molding, casting, and extrusion across key industries.

Surface Finishing

Zigitech provides expert finishing services—anodizing, painting, polishing, sandblasting, silk-screening—for standout prototypes and market-ready products.

Mass production

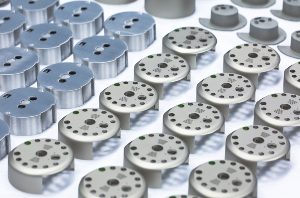

Zigitech offers in-house CNC machining for mass production—50 to 100,000+ parts—in various materials and resins with full production quality.

Why you can trust Zigitech to deliver

Quality Assurance: Careful measurement, inspection and testing are necessary to ensure the conformance of your parts. We perform multiple inspections at every step of the product development journey, from incoming material verification to final 3D scanning. You will receive complete digital files and Certificates of Compliance so you can meet your own regulatory and performance goals.That’s why we are outstanding among the rapid prototyping companies in China. Learn more about our quality control system. What's more:

Instant Quoting

Generally, quotations will be delivered in hours after submitting RFQs with clear information.

10 Years in the Industry

Having carried out rapid prototyping and rapid manufacturing for more than 10 years, our engineers have built up rich experience. We can handle all types of projects.

Massive Network Capacity

Our in-house facilities allow us to get your projects done fast. And thanks to our strong relationship with rapid manufacturing partners, our capacity is not limited.

20000+ Projects Delivered

Over 20K projects have been sent to our customers worldwide in the past 10 years, and we have received countless positive comments.

Fast Turnaround

Unlimited capacity, experienced engineers and a flexible production system allow us to create your prototype and production parts in a short period.

1000+ Happy Customers

Our goal is to keep every customer happy with reliable quality, fast turnaround and great services. We want all our new customers to become long-term customers.

Outstanding Prototyping Services from Us

Precision CNC machining

Precision CNC machining is an ideal for manufacturing high-quality, on-demand plastic or metal prototypes parts. With this technique, your parts will have tighter tolerances with better surface finishes than with other prototyping methods.

Vacumm Casting

Vacumm Casting is an

ideal rapid prototyping

technique for the

production of low-volume

and functional plastic

parts or first-run

production of plastic

parts. zigi-tech will provide

a shortcut for those who

are not ready to invest

in expensive and time-consuming mold tooling.

Rapid Tooling

Prototyping with

injection molding

provides a flexible and

reliable option for

low-volume production

runs or functional

prototyping. The

injection molded parts

can be used for full

functional and fit

testing, as well as for

various marketing

purposes.

3D printing

SLA

and SLS are two form of

3D printing or additive

manufacturing technology

that can be used to

create plastic models,

functional prototypes,

patterns, and use-end

production parts.

Sheet Metal Prototyping

Stamping, bending,

spinning. punching,

cutting & welding

standard gauge metal for

making one-off prototype

or few prototypes for

initial testing.

Low

Volume Extrusion

Aside

from low volume aluminum

die casting, investment

casting, we are offering

low volume plastic and

aluminum extrusion for

your prototyping and

shot-run production

needs.

Prototypes and Parts Delivered Fast with 4 Simple Steps

Upload a CAD File

To start, simply fill in a few information and upload a 3D CAD file.

Quote & Design Analysis

You'll receive a quote shortly, and we'll send you design for manufacturability (DFM) analysis if necessary

Order Confirmation

Once you review the quote and place your order, we'll start the manufacturing process. We also offer finishing options.

Parts are Shipped !

Your custom manufactured parts will be delivered straight to your doorstep in a short time.