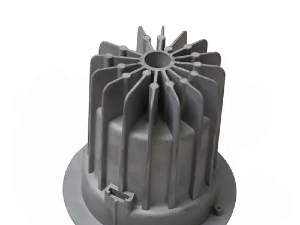

- Castable metals include aluminum, zinc and magnesium

- Mold tools can make tens of thousands of parts economically

- Surface finish and accuracy are excellent

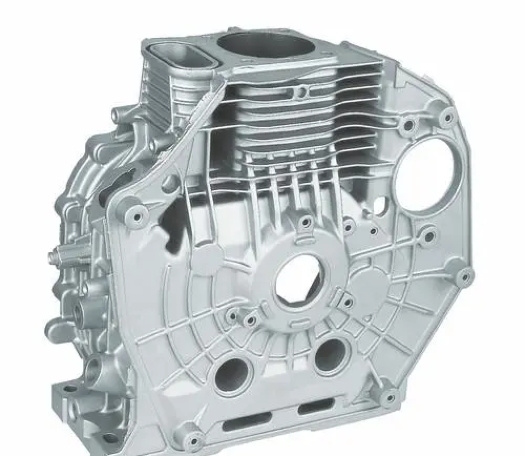

- Complex geometries can be achieved

- Especially suited for larger metal parts

A process similar to injection molding, pressure die casting is a metal casting process in which molten metal is forced into a mold cavity to create metal parts. At Zigitech, we use certified machines and pressure casting dies to form your designs from molten metal — typically zinc, copper, aluminum, magnesium, lead, pewter or other tin-based alloys. Our pressure die casting process is effective and very reliable, and can result in significant cost savings. Because of our flexibility, we can accommodate any project needs you may have – from small batches of 50 to as many as 1,000 pieces.

-

- Low cost per part when carrying out a large production run

- Excellent surface finish and dimensional stability

- Complex geometries can be made that require little or no post-machining

- Great for medium or large parts that would be slower and more expensive to machine

Why use casting instead of a more accessible process like CNC machining?

Metal casting can be used to make very large parts with high tensile strength and complex parts with undercuts. Sometimes there is no alternative.

Can you combine casting with other techniques?

We are adept at CNC machining extra features (such as engraving and minor details) onto cast parts.

How is it economically feasible for Zigitech to offer low-volume metal casting?

We have a group of reliable casting partners who fulfill our casting needs, and we use low-cost 3D printed wax patterns to reduce the price for the customer.

Is there a minimum order quantity?

We generally accept metal casting orders of no fewer than 10 units.

Quote

production today