1 Fast turnaround

Zigitech can provide up to 20 parts in 15 days or less, depending on part specification and volume.

2 Affordability

Silicone molds are less expensive than the tooling used for injection molding, resulting in low prices.

3 Capable of producing large parts

Depending on the type of equipment used, vacuum casting can to create very large parts.

4 Superior surface finish to injection molding

The vacuum process removes air bubbles and allows the material to capture fine details.

5 Color options

Coloring pigments can be added to the resin for a variety of color options.

6 Repeatability

Silicone molds can be used around 20 times before they need replacing.

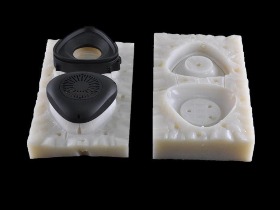

Vacuum casting is a manufacturing technology that uses a vacuum to draw liquid casting material into a mold. It differs significantly from injection molding, which pushes liquid material into a mold using a screw.

The resin part is then cured in an oven and removed from the silicone mold after cool down, which can be reused around 20 times.

Each cast part is an exact copy of the original master model. It’s a perfect solution for rapid prototyping and making small batches of quality parts.

01.

02.

03.

Vacuum Casting Technical Specifications

Typical lead time

Up to 20 parts in 15 days or less, depends on the part specification and volumes.

Minimum wall thickness

To ensure that the mold is filled properly, a wall thickness of at least 0.75 mm is necessary. For best results, we recommend a wall thickness of at least 1.5 mm

Typical quantities

Up to 25 copies per mold (depending on the mold’s complexity and the casting materials)

Accurate

± 0.3%

(with lower limit on ± 0.3 mm on dimensions smaller than 100 mm)

Maximum part dimensions

The size of the mold is limited by the dimensions of the vacuum chamber (1900 x 900 x 750 mm) and by the volume of the product (maximum volume: 10 liters)

Color & Finishing

Pigment is added to the liquid polyurethane prior to casting, custom painting and texture.

Vacuum casting is a more affordable alternative to IM, especially in low volumes. It also offers unique advantages like an excellent surface finish.

Vacuum casting is best for making visually impressive prototypes, but it can also be used for non-mechanical end-use parts like cases and covers.

The silicone molds used in vacuum casting have a short lifespan, typically around 20 moldings, so we dispose of them after use.

If you wish to keep the 3D printed or CNC machined master model, talk to us directly.