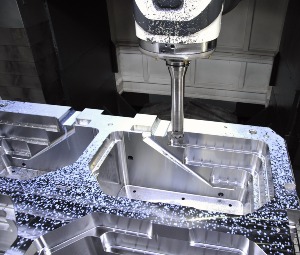

From prototype mold, we can produce high-quality moldings which are very close to mass production, or 100% matching the final production level.

Rapid production tooling gives a number of advantages over other mothods of prototype production:

- Fast processing: Prototype tooling provides quick results, so the transition between development and production is very short.

- Customization: The rapid tooling process still allows for advanced customization of the mold.

- Proof of concept/testing: Rapid prototyping facilitates practical real-world design testing and troubleshooting solutions. It also enables quick and precise production of new tooling that implements design changes and improvements.

- Speed to market: Fast production and accurate tooling contribute to efficiency in production, ultimately providing a faster introduction to the market than other methods.

- Competitive pricing: The affordability of the rapid tooling process translates into a positive impact on the bottom line for our customers.

Why should I use rapid tooling?

Rapid tooling is a fast and cost-efficient way to create a few prototypes in a selected material for function and aspect testing, as well as for low-volume manufacturing to test out the market.

How fast can I get the moldings?

This depends on the size and geometry of the parts. For a common open and shut mold with regular size part such as 300 x 300 x 50 mm, fabrication of tools and moldings can be done within 10 days.

What materials can I choose from with rapid tooling?

There is no limit to material choice. Any plastics available for mass production, including common silicone and rubber materials, can also be used with the rapid tooling process.

What is the quality level of rapid tooling?

Moldings from rapid tooling are end-use-parts quality. They are very close to mass production parts.

How many moldings can I get from rapid tooling?

Normally, aluminum molds are good enough for +/- 1,000 shots, while Steel P20 molds can last for +/- 10,000 shots.