Zigitech is an experienced provider of mold making services with lots to offer beyond our competitors:

1. Fast DFM reports

Although we check your design feasibility when providing a quote, we can provide a fast and thorough DFM (design for manufacturability) report before production begins. In the DFM report, we’ll identify any errors or issues that might cause a manufacturing problem down the line.

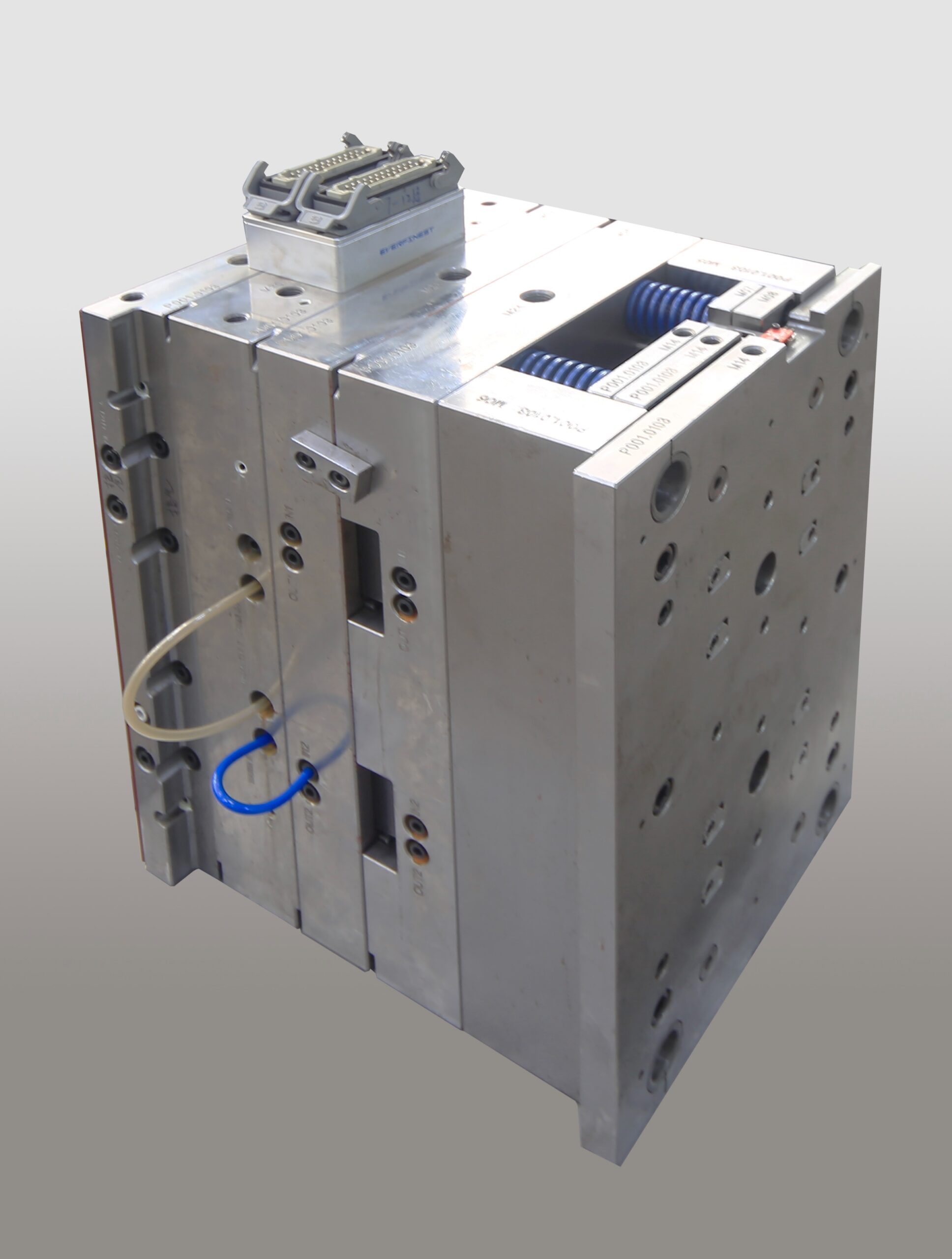

2. Wide range of molds

We offer several different types of molds, which means you can avoid splitting your projects; just send everything to us to ensure your project runs smoothly.

3. Fast Turnaround

Our large facility and machining capabilities allow us to build molds quickly, whatever the application or material, which means you can get your moldings completed faster.

4. Molding Capabilities

Zigitech can ship your molds to you directly, but we can also handle injection molding and other production services to deliver you prototypes and final parts using those molds.

What is mold making and when do you need it?

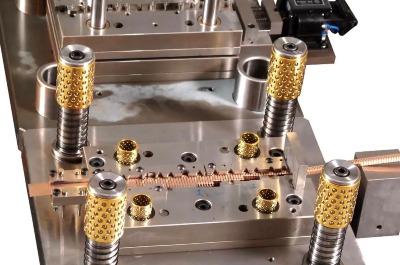

Molds are normally created to duplicate plastic and metal parts. After testing the prototypes and the market, it is the most cost-efficient way to launch your products at scale.

How long does a mold last?

A well-made, fully harden steel mold may be used for up to a million shots or injections, depending on the mold shape and injection material. Aluminum molds are less durable, which is good for short-run production with tight schedule.

Can molds be any shape?

Molding designs should avoid sharp corners, inconsistent wall thicknesses, and other features that restrict material flow.

Should I choose a locally produced mold or an exported mold?

Generally speaking, making plastic or metal molds (and moldings) is cheaper in China than other countries. But shipping costs should also be considered: you will need to use air freight if you have a tight schedule; sea freight is much cheaper, but will usually take 40 days or more.

When do I need full automatic mold?

Whatever you decide to use, in the end, what is the best cost-efficient way to get your parts done in the required quality is the key.